By Niels Hagège, Director, Business Development and Partnerships at Cycle Momentum and Thibault Beudin, Communication Officer at Cycle Momentum

As we work toward a more sustainable future, managing materials from aging wind farms has become increasingly important. Wind energy plays a key role in reducing global carbon emissions, but it is crucial to handle turbine materials responsibly at the end of their lifecycle. The wind industry, recycling companies, and blade manufacturers are collaborating to develop innovative recycling solutions. This is particularly true for Quebec, where a unique initiative spearheaded by RECYC-QUÉBEC and Cycle Momentum is taking steps to address this challenge.

Introduction to Renewable Energy

Renewable energy is a vital component of the world’s transition to a sustainable future. Wind energy, in particular, has become a significant contributor to the global electricity mix, with wind turbines generating over 6% of the world’s electricity in 2020. The wind industry has grown substantially over the past 40 years, with wind energy powering millions of homes and businesses every day. In the United States, wind energy is the largest source of renewable electricity generation, providing 9.8% of the country’s electricity. As the demand for renewable energy continues to rise, the importance of sustainable practices in the wind industry cannot be overstated.

A Collaborative Model to Circularity

The Wind Turbine Circular Innovation Challenge focused on eco-design, reuse, and recycling of wind turbine materials.

This initiative not only detects technological solutions for wind energy circularity challenges but also holds valuable lessons and ingredients to tackle this circular issue for other industries such as transportation, mining, construction, and chemicals.

Key Factors Driving Success

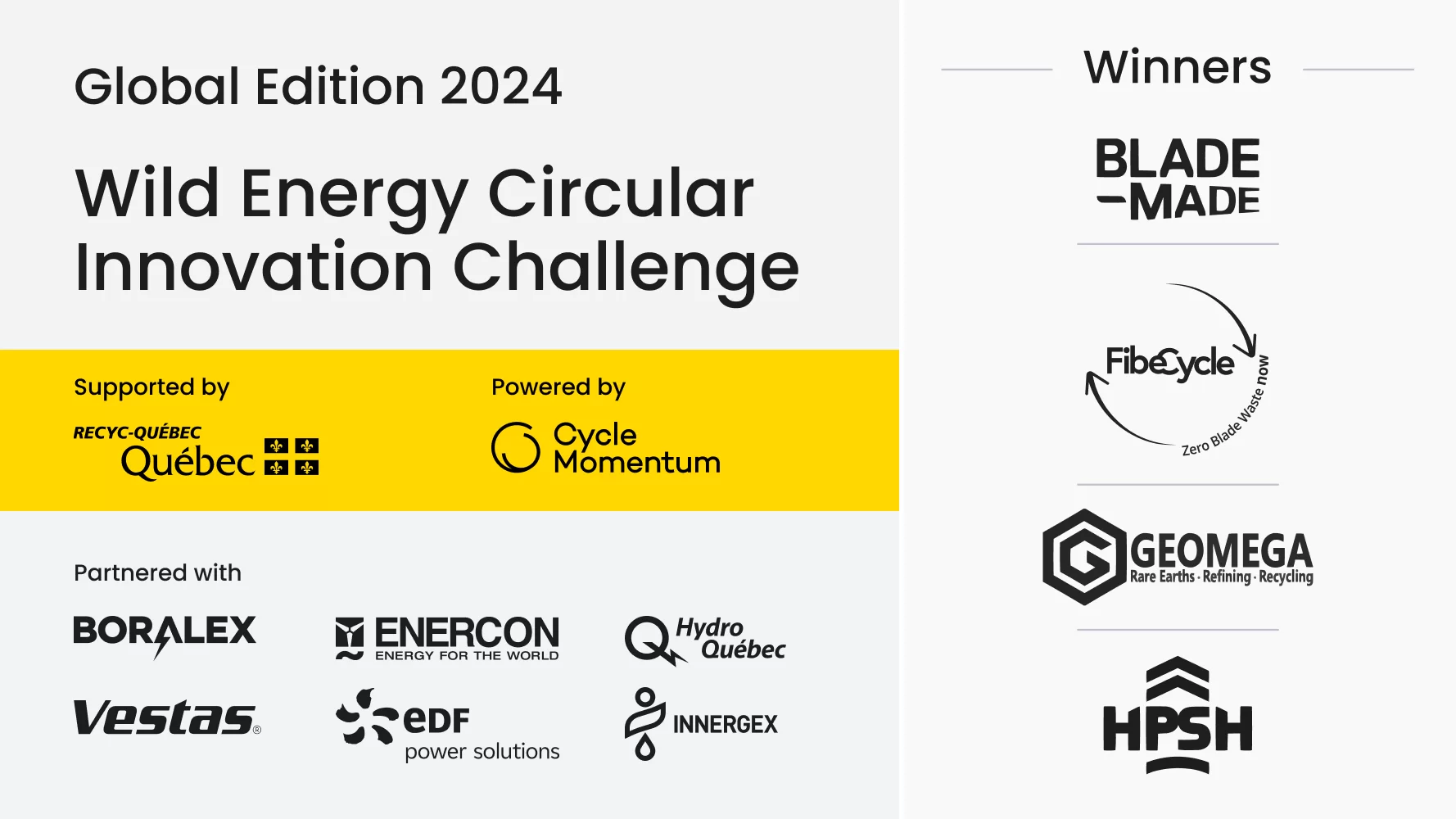

RECYC-QUÉBEC: Driving Recycling Innovation

As a cornerstone of this initiative, RECYC-QUÉBEC plays a vital role in Quebec’s recycling and circular economy sectors. By 2030, Quebec will need to manage over 125,000 tonnes of wind energy materials with many wind turbines approaching the end of their lifecycle.

Managing this growing waste stream is more urgent than ever. RECYC-QUÉBEC is leading the charge to help the wind turbine industry structure itself in recycling, repurposing the growing volume of decommissioned turbines.

Cycle Momentum: Bridging Innovation and Industry

Cycle Momentum acts as a key connector between innovators and the industrial ecosystem. With a keen eye for promising global technologies, Cycle Momentum supports the scouting and evaluation phases of the project as well as the development of pilot projects that enable testing innovations under operational conditions. Manufacturers play a crucial role in developing recycling solutions for wind turbine blades.

This approach ensures that the innovations selected are not just cutting-edge, but also practical and scalable.

Industry Collaboration: Fostering Diverse Perspectives to mitigate risks

Collaboration with industry leaders strengthens the initiative’s potential for success.

These partners bring diverse expertise, spanning areas ranging from wind turbine manufacturing (ENERCON, VESTAS) to wind farm operations (BORALEX, EDF RENEWABLES, INNERGEX) and electricity producer (HYDROQUEBEC).

By fostering this diverse, multi-stakeholder approach, the initiative ensures that the technologies proposed are both effective and scalable. Furthermore, the involvement of key stakeholders from various sectors creates a robust platform for knowledge-sharing and continuous solution refinement.

Testing Innovations in Real-world Settings

Testing new technologies under real-world conditions is essential for ensuring their effectiveness and long-term success. Advancements in recycling technology are crucial for the wind energy sector. Cycle Momentum, in collaboration with sector experts, offers comprehensive support for pilot projects, allowing promising technologies to be tested, validated, and integrated into the practices of the wind energy industry.

These pilots build trust in emerging solutions and accelerate their readiness for large-scale deployment.

Extending Circularity Beyond Wind Power Sector

While the wind energy sector is the current focus, the collaborative model developed through this initiative holds promise for other industries. Sectors such as transportation, mining, construction, and chemicals also face significant sustainability challenges. By adopting this partnership-driven approach—which unites industry leaders, and supportive institutions, circularity experts and innovation hubs —these industries can also move closer to circularity.

The Windturbine Circular Innovation Challenge serves as a case study, demonstrating how effective collaboration leads to tangible, impactful results. Through diverse partnerships, knowledge-sharing, and practical solution testing, industries beyond wind energy can make significant progress toward a sustainable, circular economy.

Looking Ahead: Driving Collective Action for Sustainability

At Cycle Momentum, we remain committed to advancing circularity in every aspect of our work. We are proud to be part of a collaborative effort shaping the future of the clean tech ecosystem in Quebec and beyond. With the right support and an openness to explore new ideas, we can collectively build a more sustainable future.

The Challenge of Turbine Blades

Wind turbine blades, typically made from composite materials such as fiberglass and carbon fiber, pose a significant challenge when it comes to recycling. The blades, which can reach lengths of over 110 meters, are difficult to recycle due to their complex composition. As a result, many decommissioned wind turbine blades end up in landfills, contributing to the growing problem of waste management in the wind industry. However, with the development of new recycling technologies and processes, it is now possible to recycle wind turbine blades and reduce the industry’s waste. Established recycling practices, such as mechanical recycling and chemical recycling, are being improved and expanded to accommodate the growing number of decommissioned blades.

Recycling Solutions for Blade Materials

Recycling solutions for wind turbine blades are becoming increasingly important as the number of decommissioned blades continues to rise. Companies like Veolia and Global Fiberglass Solutions are developing innovative recycling processes that can convert wind turbine blades into raw materials, such as cement and composite materials. These materials can then be used to manufacture new products, reducing the need for virgin materials and minimizing waste. The recycling process typically involves collecting and sorting the blades, followed by shredding and processing into usable materials. New materials, such as recyclable epoxy resins, are also being developed to make wind turbine blades more sustainable and easier to recycle.

The Importance of a Circular Economy

A circular economy is essential for the sustainable development of the wind industry. By adopting circular economy practices, such as recycling and reusing materials, the industry can reduce its waste and minimize its environmental impact. The use of recyclable materials, such as those developed by Siemens Gamesa, can also help to reduce carbon dioxide emissions and promote sustainable manufacturing processes. As the wind industry continues to grow, it is crucial that companies prioritize sustainability and adopt circular economy practices to ensure an environmentally friendly future. This includes developing new recycling technologies, improving manufacturing processes, and promoting the use of recyclable materials.

Wind Energy and Sustainability

Wind energy is a crucial component of a sustainable future, providing a clean and efficient source of electricity. However, the industry must prioritize sustainability and adopt environmentally friendly practices to minimize its impact on the environment. This includes developing sustainable manufacturing processes, reducing waste, and promoting the use of recyclable materials. By adopting a circular economy approach, the wind industry can reduce its carbon footprint and contribute to a more sustainable future. As the demand for renewable energy continues to rise, the importance of sustainability in the wind industry will only continue to grow, driving innovation and investment in recycling solutions, new materials, and sustainable practices.

Blade Recycling Innovations in Modern Wind Farms

The rapid expansion of wind farms across Quebec and globally has accelerated the need for practical blade recycling solutions. Modern wind turbine blades, particularly those from offshore wind turbines, present unique challenges due to their massive size and composite materials. Companies like Carbon Rivers are pioneering pyrolysis methods that apply intense heat to break down blades into reusable glass fibers and resin components, while the National Renewable Energy Laboratory (NREL) explores milder chemical processes to preserve material quality. These advancements aim to divert decommissioned wind turbine blades from landfills and reintegrate recycled blade materials into new industrial applications, such as construction materials for roads or composite manufacturing.

Circular Economy Strategies for Wind Turbine Components

The wind industry is embracing circular economy principles to address the lifecycle of turbine components:

- Rotor blade repurposing: Shredded blades reused as raw materials for cement production

- Steel tower recycling: 90% of tower materials already recyclable through existing scrap processes

- Nacelle component recovery: Rare earth metals and copper rewired for new turbines

Quebec’s Wind Turbine Circular Innovation Challenge, supported by RECYC-QUÉBEC, demonstrates how regional wind farms can collaborate with recyclers to close the loop on blade materials. This model shows particular promise for offshore wind turbines, where blade replacement cycles occur more frequently due to harsh marine conditions.

Policy and Industry Collaboration for Blade Recycling

Effective wind turbine blade recycling requires coordinated action:

Initiative

- Extended Producer Responsibility (EPR) laws

- DOE funding for Carbon Rivers

- RECYC-QUÉBEC’s 2030 targets

Impact

- Mandate manufacturers to manage blade waste

- Scales pyrolysis technology to full commercial capacity

- Diverts 125,000 tonnes of blade materials from landfills

These efforts align with Cycle Momentum’s work to connect electricity producers like Hydro-Québec with innovators developing sustainable processes for blade materials. By treating decommissioned wind turbine blades as valuable feedstock rather than waste, the wind industry can reduce reliance on virgin resources while maintaining its role as a leader in renewable electricity generation.

Next-Gen Materials for Sustainable Wind Turbines

The future of blade recycling lies in design innovation:

- Thermoplastic resins: Enable repeated melting/reforming of blade materials

- Bio-based composites: Combine natural fibers with recyclable polymers

- Modular blade designs: Simplify disassembly for material recovery